Post Code:511400

Email:sales@blaccessory.com

whatsApp:+86 18028696007

Beauty brands often struggle with unreliable suppliers who compromise product quality and delivery schedules. Wrong supplier choices lead to inventory shortages, customer complaints, and damaged brand reputation in competitive markets.

Evaluate suppliers based on production capacity, quality certifications, delivery speed, and manufacturing experience. Look for BSCI and ISO-9001 certified facilities with proven track records in North American and European markets.

#cosmetic bag supplier evaluation criteria

I learned this the hard way when a previous supplier promised everything but delivered substandard products three weeks late. That experience taught me the critical importance of thorough supplier evaluation before committing to large orders.

Manufacturing quality cosmetic bags requires understanding production processes, material selection, and quality control systems. Professional manufacturing involves multiple specialized steps that determine final product durability and appearance.

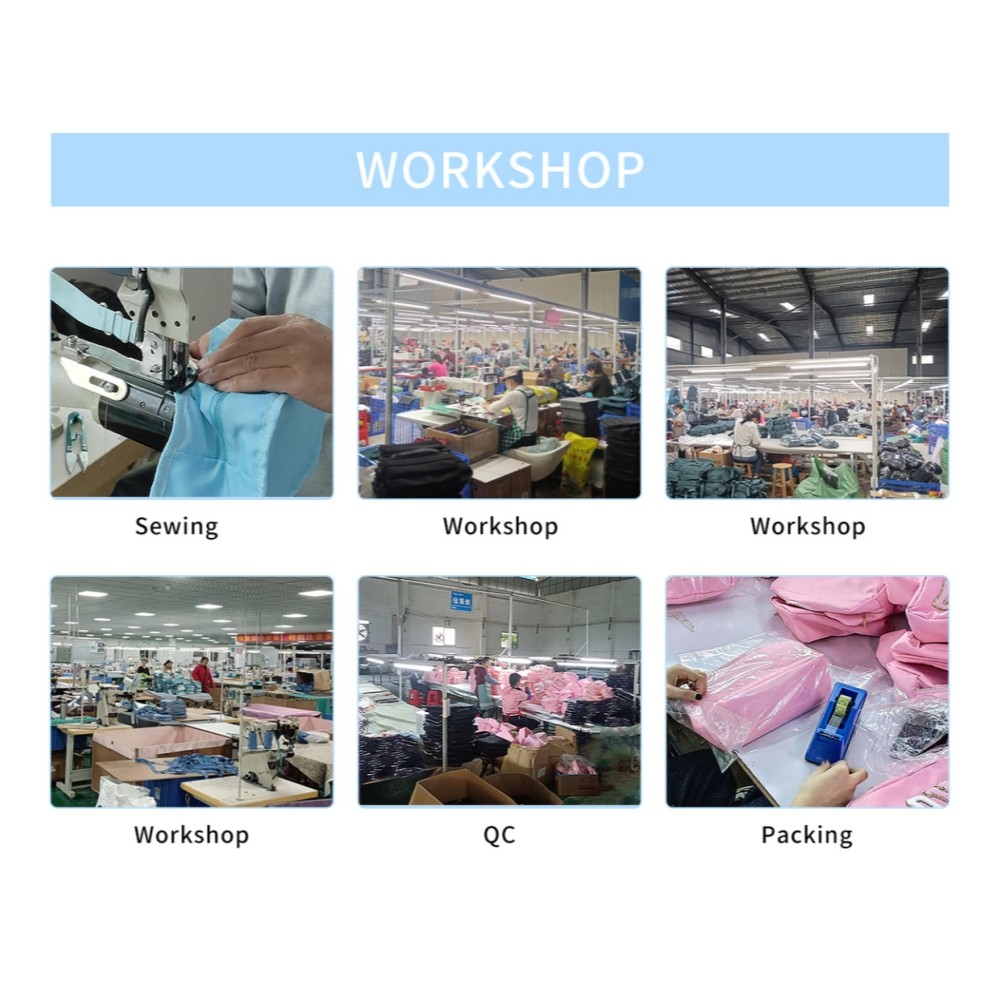

Cosmetic bag manufacturing involves pattern design, material cutting, sewing assembly, quality inspection, and packaging. Professional facilities use industrial sewing machines, skilled workers, and systematic quality control to ensure consistent results meeting international standards.

#cosmetic bag manufacturing process

Manufacturing begins with precise pattern development based on customer specifications and market requirements. Our design team creates templates that optimize material usage while ensuring proper construction geometry. Pattern accuracy determines final product dimensions and affects manufacturing efficiency throughout production cycles.

Material selection significantly impacts manufacturing complexity and final product quality. Premium PU leather requires specialized cutting techniques to prevent edge fraying and maintain consistent thickness. Waterproof fabrics need sealed seam construction using specialized equipment. Lining materials must coordinate with exterior finishes while providing functional protection.

Cutting processes demand precision equipment and experienced operators for consistent results. Computer-controlled cutting systems ensure pattern accuracy and minimize material waste. Hand cutting requires skilled workers who understand fabric behavior and grain direction. Quality cutting prevents assembly problems that compromise structural integrity.

Sewing assembly represents the most critical manufacturing phase requiring skilled operators and quality equipment. Our 60 industrial sewing machines handle different construction requirements from basic seams to complex reinforcement stitching. Zipper installation demands specialized presser feet and experienced sewists. Handle attachment points need reinforcement stitching for durability.

Quality control occurs throughout manufacturing rather than only at final inspection stages. Material inspection prevents defective components from entering production. In-process checks catch construction errors before they compound into major defects. Final inspection ensures products meet specifications before packaging and shipping.

Production capacity affects delivery schedules and order fulfillment reliability significantly. Our 120 skilled workers enable rapid production scaling for large orders without compromising quality standards. Machine capacity determines daily output limits and delivery timeline commitments. Workforce training ensures consistent quality across different production shifts.

Lead time management becomes critical for seasonal demand and promotional product launches. Raw material procurement requires advance planning to prevent production delays. Production scheduling coordinates multiple orders while maintaining delivery commitments. Our fast delivery capability gives clients competitive advantages in dynamic markets.

Customization capabilities attract private label customers seeking unique product differentiation. Logo application methods include embroidery, screen printing, and heat transfer depending on material compatibility. Color matching requires precise dye lot control and quality standards. Size modifications need pattern adjustments that maintain structural integrity.

Equipment investment affects manufacturing capability and product quality consistency. Modern sewing machines produce superior stitch quality and operate more reliably. Specialized equipment enables complex construction techniques that inferior facilities cannot execute. Our equipment investment supports quality standards that major brands require.

Worker training programs ensure consistent quality across production teams and shifts. Skilled sewists understand construction techniques that prevent common defects. Quality awareness training helps workers identify problems before they affect finished products. Continuous improvement programs incorporate new techniques and efficiency improvements.

Material sourcing requires established relationships with reliable suppliers for consistent quality and availability. Fabric suppliers must meet quality standards and delivery schedules. Hardware suppliers provide zippers, handles, and fittings that meet durability requirements. Our supplier relationships ensure material availability for rapid production scaling.

Testing protocols verify product durability and functionality before shipment to customers. Zipper cycle testing ensures reliable operation through expected product lifetime. Stress testing evaluates handle and strap attachment strength. Water resistance testing verifies protective capabilities for sensitive contents.

Packaging systems protect finished products during shipping while presenting professional appearance. Individual polybag packaging prevents contamination and damage during handling. Retail packaging must appeal to end customers while protecting product integrity. Bulk packaging optimizes shipping efficiency for wholesale customers.

Certification requirements enable access to major brand customers requiring compliance verification. BSCI certification demonstrates social responsibility and ethical manufacturing practices. ISO-9001 quality management systems ensure consistent production standards. These certifications differentiate professional manufacturers from informal suppliers.

Production planning coordinates material procurement, manufacturing schedules, and delivery commitments effectively. Demand forecasting helps optimize inventory levels and production capacity. Master production scheduling balances multiple customer orders while maintaining efficiency. Our planning systems enable short delivery times that provide competitive advantages.

Cost management affects pricing competitiveness while maintaining quality standards and profitability margins. Material costs represent significant portions of total manufacturing expenses. Labor efficiency improvements reduce per-unit costs without compromising quality. Overhead allocation ensures accurate pricing for different product complexity levels.

Quality systems ensure consistent results across different production batches and time periods. Standard operating procedures document best practices for consistent execution. Quality metrics track performance trends and identify improvement opportunities. Our quality focus enables long-term partnerships with demanding international customers.

Technology integration improves manufacturing efficiency and product quality while reducing costs. Computer-aided design systems optimize patterns and reduce development time. Production tracking systems monitor progress and identify bottlenecks immediately. Quality management software documents inspections and maintains traceability records.

Supplier relationship management affects manufacturing capability and delivery reliability significantly. Long-term partnerships with material suppliers ensure priority service and quality consistency. Technical cooperation develops improved materials and construction methods. Our established relationships support rapid scaling for growing customer requirements.

Environmental considerations increasingly influence manufacturing decisions and customer preferences. Waste reduction programs minimize environmental impact while reducing costs. Sustainable material options appeal to environmentally conscious brands and consumers. Our environmental initiatives support customers’ sustainability goals and corporate responsibility requirements.

Market knowledge helps manufacturers understand customer requirements and industry trends affecting product development. Fashion trend awareness influences color and style planning. Functional requirement evolution drives construction innovation and feature development. Our market experience guides customers toward successful product decisions.

| Manufacturing Aspect | Key Requirements | Quality Impact | Timeline Effect |

|---|---|---|---|

| Pattern Design | Precision templates | Fit and function | 2-3 days |

| Material Cutting | Accurate equipment | Waste reduction | 1 day |

| Sewing Assembly | Skilled operators | Durability | 3-5 days |

| Quality Control | Systematic inspection | Defect prevention | 1 day |

| Packaging | Professional presentation | Brand image | 0.5 days |

Choose suppliers with proven manufacturing capability, quality certifications, and fast delivery systems that support your brand’s growth and quality requirements.

Cosmetic bag manufacturers, custom cosmetic bags, cosmetic bag factory, bulk canvas cosmetic bags, wholesale bulk cosmetic bags, beauty, skin, PVC.

Hair Accessories: Hair ties, hair clips, headbands, and hairbands. Chic, stylish, suitable for any occasion.

Copyright © 2025 Bling Accessory Co., Ltd. | All Rights Reserved.