Post Code:511400

Email:sales@blaccessory.com

whatsApp:+86 18028696007

| MOQ: | 10 Pcs |

|---|---|

| PAYMENT: | T/T, Western Union, Alibaba Trade Assurance |

| Port: | Guangzhou |

| Lead time: | 15 Days |

| Samples: | $10.00/Piece | 1 Piece (Min. Order) |

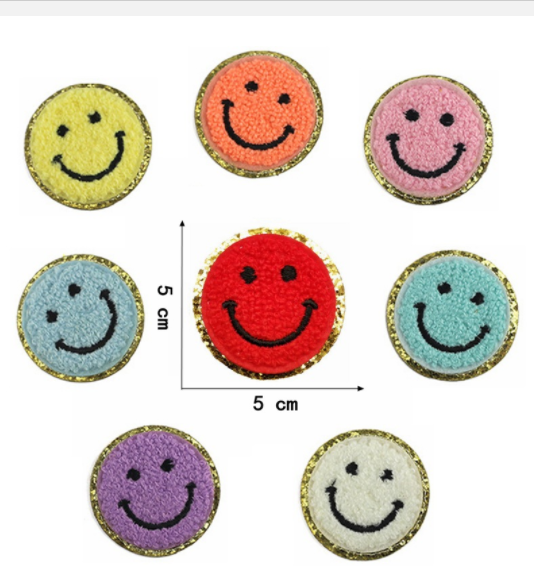

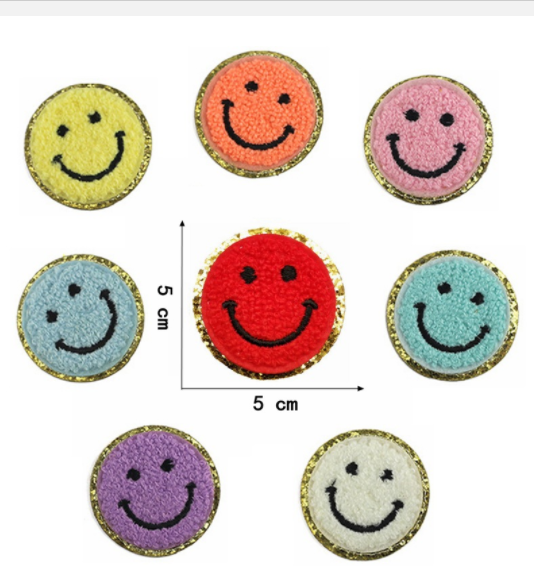

| Customization: | Custom Color&Custom Logo |

| Delivery Time: | 7 Days |

| Certification: | OEKO-TEX STANDARD 100, CPSIA, TUV |

Cosmetic bag manufacturers, custom cosmetic bags, cosmetic bag factory, bulk canvas cosmetic bags, wholesale bulk cosmetic bags, beauty, skin, PVC.

Hair Accessories: Hair ties, hair clips, headbands, and hairbands. Chic, stylish, suitable for any occasion.

Copyright © 2025 Bling Accessory Co., Ltd. | All Rights Reserved.